How to Optimize Chemical Manufacturing Processes for Increased Efficiency

In today's fast-paced industrial landscape, the need for increased efficiency in chemical manufacturing processes has never been more crucial. Experts in the field emphasize the importance of optimizing operations to not only reduce costs but also enhance productivity. Dr. Jennifer Harlow, a recognized leader in chemical engineering, once stated, "Efficiency in chemical manufacturing is not just a goal; it's a necessity for sustainable growth." This perspective underscores the significance of identifying areas for improvement within manufacturing workflows, machinery utilization, and resource management.

As the demand for high-quality chemical products grows, manufacturers face the challenge of developing methods that minimize waste while maximizing output. Implementing newer technologies, incorporating data analytics, and fostering a culture of continuous improvement are essential strategies in this optimization journey. By understanding the intricacies of chemical processes and leveraging advanced methodologies, companies can achieve substantial increases in efficiency. Such advancements not only benefit the bottom line but also contribute to environmental sustainability, ensuring that the future of chemical manufacturing aligns with evolving industry standards and regulations.

Assessing Current Chemical Manufacturing Processes for Improvement

In assessing current chemical manufacturing processes for improvement, it is vital to begin with a thorough evaluation of existing workflows and technologies. According to the 2022 Chemical Industry Outlook Report by the American Chemistry Council, over 70% of chemical manufacturers are optimizing their operations to achieve higher efficiency and sustainability. An in-depth analysis may include mapping out process flows, identifying bottlenecks, and evaluating resource utilization. By applying methodologies such as Six Sigma or Lean Manufacturing, companies can systematically target inefficiencies and enhance overall productivity.

**Tips for Process Assessment:**

1. Conduct a value stream mapping session to visualize the entire production process and pinpoint areas of waste.

2. Utilize Key Performance Indicators (KPIs) to track resource usage, cycle times, and defect rates, helping to quantify areas for improvement.

3. Involve cross-functional teams to gather diverse insights and foster a culture of continuous improvement throughout the organization.

Investing in advanced technologies, such as process automation and data analytics, is another vital area for consideration. The 2023 Global Process Automation Report highlights that integrating smart manufacturing solutions can result in a 20-30% reduction in operational costs. By leveraging real-time data and predictive analytics, chemical manufacturers can make informed decisions that enhance efficiency, reduce downtime, and improve product quality. Establishing a culture of innovation and continuous assessment will prepare companies to navigate challenges and keep pace with industry advancements.

Identifying Key Efficiency Metrics in Chemical Production

In the realm of chemical production, identifying key efficiency metrics is crucial for optimizing manufacturing processes. These metrics serve as benchmarks that help organizations understand their operational performance and pinpoint areas for improvement. Critical efficiency indicators may include yield rates, cycle times, and energy consumption. Yield rates reflect the percentage of product generated relative to the raw materials utilized, providing insights into how effectively resources are converted into finished products. Cycle time, the duration required to complete a batch from start to finish, highlights the efficiency of production scheduling and processes.

Additionally, monitoring energy consumption is essential, as it directly correlates with operational costs and environmental impact. By analyzing energy usage relative to production output, manufacturers can assess whether they are using resources effectively or if adjustments are necessary. Furthermore, integrating data analytics can enhance the assessment of these metrics, enabling real-time monitoring and facilitating swift corrective actions. As companies strive for increased efficiency in chemical production, focusing on these key metrics will empower them to streamline their operations and achieve sustainability goals while maximizing profitability.

Optimizing Chemical Manufacturing Processes: Efficiency Metrics

Implementing Lean Manufacturing Techniques in Chemical Processes

Lean manufacturing techniques can significantly enhance the efficiency of chemical manufacturing processes. By streamlining operations, reducing waste, and improving resource management, these techniques help organizations maximize their output while minimizing costs. One key principle of lean manufacturing is the identification and elimination of non-value-added activities, which often plague chemical processes. Techniques such as value stream mapping can be employed to visualize the entire process and pinpoint areas for improvement. By focusing on only those activities that contribute directly to the value of the product, companies can create more efficient workflows that enhance productivity.

Another important aspect of implementing lean methodologies in chemical manufacturing is fostering a culture of continuous improvement, known as Kaizen. This approach encourages employees at all levels to contribute ideas for process enhancements and efficiency gains. Regular training and workshops can equip personnel with the skills to identify bottlenecks, reduce cycle times, and improve safety standards. By creating an environment that values employee input and promotes collaborative problem-solving, organizations can drive ongoing improvements that adapt to changing market demands and technological advancements. The result is a more resilient and competitive chemical manufacturing operation that harnesses the full potential of lean principles.

Leveraging Technology and Automation to Enhance Efficiency

Leveraging technology and automation is pivotal for enhancing efficiency in chemical manufacturing processes.

By integrating advanced digital tools, manufacturers can achieve real-time monitoring and control over their operations.

Utilizing IoT sensors, for example, allows for continuous data collection on variables such as temperature, pressure, and flow rates.

This data can be analyzed to not only identify inefficiencies but also to predict equipment failures before they occur,

reducing downtime and maintenance costs.

Furthermore, automation plays a crucial role in standardizing production processes. Automated systems can execute repetitive tasks with high precision, minimizing human error and ensuring consistent product quality. Robotic process automation can streamline material handling, mixing, and packaging, allowing for faster production cycles. Additionally, by implementing machine learning algorithms, manufacturers can optimize resource allocation and inventory management, thus reducing waste and improving overall operational efficiency. Embracing these technological advancements positions chemical manufacturers to meet increasing market demands while maintaining cost-effectiveness and sustainability.

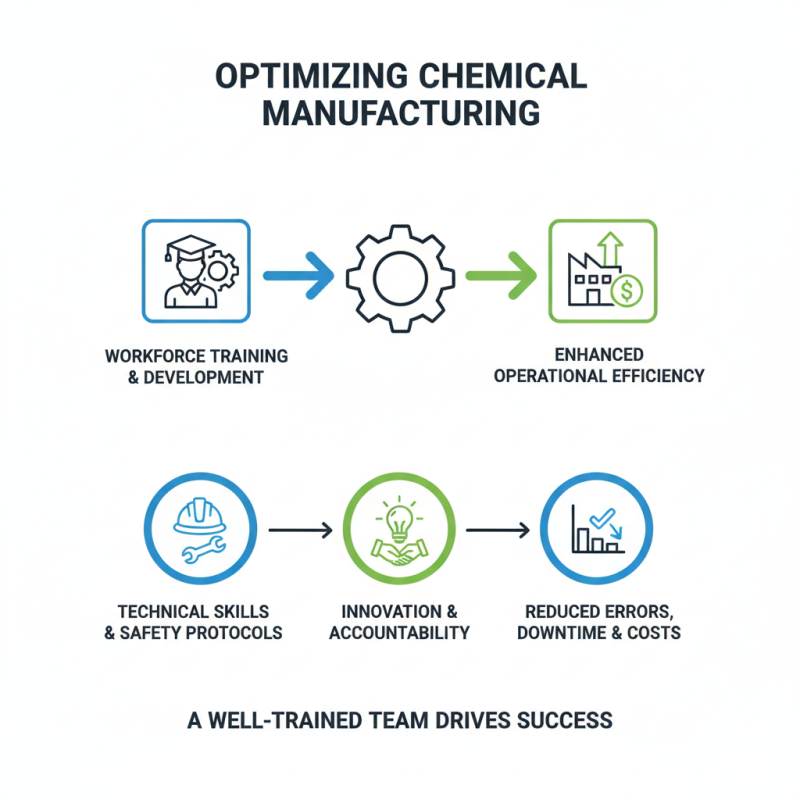

Training and Developing Workforce for Optimal Chemical Operations

In optimizing chemical manufacturing processes, the role of workforce training and development cannot be overstated. A well-trained workforce drastically enhances operational efficiency by ensuring that employees are equipped with the necessary skills and knowledge to perform their tasks effectively. Continuous training programs that focus on both technical skills and safety protocols enhance not only the individual capabilities of workers but also foster a culture of innovation and accountability within the organization. This can lead to significant reductions in errors, downtime, and operational costs.

Moreover, developing a workforce that is adaptable to changing technologies and processes is essential in today’s fast-paced chemical industry. Employers can implement mentorship programs and cross-training initiatives to build a versatile workforce that can seamlessly integrate new methodologies and equipment. Regular assessments and feedback loops can further ensure that training programs remain relevant and specific to the operational challenges faced by the organization. By investing in personnel development, chemical manufacturers can achieve not only increased efficiency but also a strong competitive edge in the marketplace.

Related Posts

-

Top Trends in Chemical Manufacturing for Sustainable Development

-

Top 10 Trends Transforming the Fine Chemical Industry in 2024: Insights and Data

-

What is a Catalyst in Catalysis? Understanding Their Role and Impact in Chemical Reactions

-

What is the Role of Catalysts and Technologies in Advancing Green Energy Solutions?

-

How to Accelerate Your Catalysis Research for Breakthrough Discoveries