2026 Best Strategies for Chemical Process Development Techniques?

In the rapidly evolving field of chemical process development, companies face numerous challenges. The need for efficiency, sustainability, and innovation drives the search for the best strategies. As new technologies emerge, the landscape of chemical process development becomes increasingly complex.

Effective techniques are crucial for achieving optimal results. Understanding process conditions can lead to better yields and reduced costs. However, many organizations struggle to adapt to these advances. There is often a gap between theory and practical implementation. This prompts reflection on existing methods and a call for improvement.

Exploring various strategies will reveal insights into successful practices. Each organization's unique challenges will shape their approach. Continuous learning and adaptation are vital for success in chemical process development. The future demands flexibility and creativity to keep pace with change.

Overview of Chemical Process Development Techniques

Chemical process development is a complex journey. It requires a mix of understanding chemistry, engineering, and project management. Techniques vary widely, each with advantages and drawbacks. One common method is the use of simulation software. These tools allow engineers to visualize processes before they are built. However, results can be misleading if the input data is inaccurate.

Another strategy involves lab-scale experiments. Performing small-scale tests helps identify challenges early. Lab work can reveal unexpected reactions or inefficiencies. Yet, scaling these findings to larger operations often introduces new variables that complicate the process. Many teams struggle with these transitions.

Collaboration is crucial in chemical process development. Engineers, chemists, and marketers must communicate effectively. A lack of clarity can lead to costly mistakes. Regular meetings are essential, but it’s easy for them to become unproductive. Maintaining focus on the goals is vital, yet often overlooked. The path to innovation is not always straightforward and may require frequent adjustments along the way.

Key Factors Influencing Chemical Process Design

When designing chemical processes, several key factors emerge as crucial. The choice of raw materials can significantly affect the overall efficiency. High-quality feedstocks may lead to a smoother operation. However, they can also increase costs. This is a delicate balance that needs careful consideration.

Another critical element is the reaction conditions. Temperature and pressure directly influence the reaction rates and yields. Inadequate conditions can lead to suboptimal results. Engineers often grapple with this. They must weigh safety and economic viability while optimizing these parameters.

Finally, process scalability should not be overlooked. A method that works well on a small scale may falter in larger applications. Scaling up can introduce new challenges. Transitioning from lab to production often uncovers unforeseen issues. These hurdles require thorough evaluation and strategic planning.

2026 Best Strategies for Chemical Process Development Techniques

Innovative Approaches in Reaction Pathway Optimization

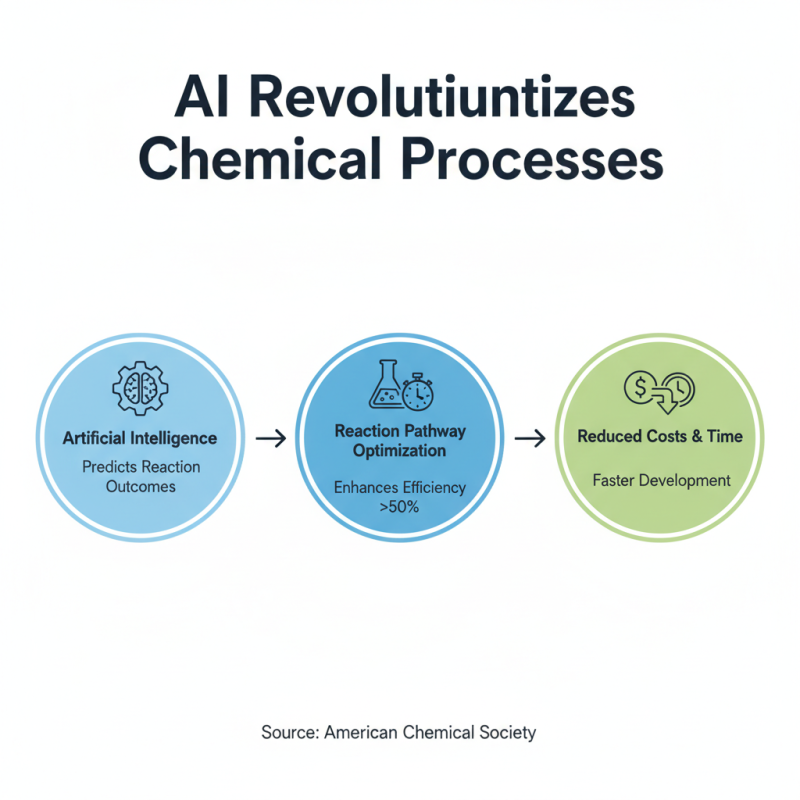

Innovative approaches in reaction pathway optimization are redefining chemical process development. Researchers are leveraging artificial intelligence to predict reaction outcomes with remarkable accuracy. According to the American Chemical Society, AI can enhance reaction efficiency by over 50%. This significant improvement reduces costs and time.

One promising technique involves multi-objective optimization. This approach balances yield, selectivity, and environmental impacts. However, challenges remain in integrating complex reaction data. Many chemical processes generate vast amounts of information, making it tough to analyze effectively. The 2023 Chemical Engineering report indicates that about 30% of data generated is not utilized efficiently. This gap points to the need for more robust data handling strategies.

Moreover, traditional methods often overlook the role of kinetics in the optimization process. There's a tendency to rely on established reaction mechanisms without critically assessing their validity. A recent study highlighted that 25% of industrial reactions could be performed more optimally by reevaluating kinetic parameters. Innovation must include a willingness to question existing processes. Embracing uncertainty can lead to breakthroughs in this evolving field.

Technological Tools for Enhanced Process Development

The landscape of chemical process development is evolving rapidly. Technological tools are at the forefront of this change. A report from the American Institute of Chemical Engineers indicates that 70% of companies are investing in digital tools for process optimization. These tools enhance efficiency, speed, and safety in chemical manufacturing.

Artificial intelligence and machine learning are transforming traditional methods. They allow for real-time data analysis and predictive modeling. A study found that AI can improve production yields by up to 20%. However, the integration of these technologies poses challenges. Many companies struggle with data management and skill gaps among staff. There’s also a risk of over-reliance on algorithms, which can lead to oversight in critical decision-making.

Process simulation software has made significant strides as well. It provides visual representations that help engineers understand complex systems. According to recent industry data, simulations can reduce development time by 30%. However, these tools require accurate input data. Poor data quality can lead to misleading outcomes, leaving room for improvement in data collection practices. Balancing innovation with practical limitations is essential in this advancing field.

Sustainability Considerations in Chemical Process Engineering

Sustainability is critical in chemical process engineering. It involves developing methods that minimize environmental impact. Engineers face challenges in balancing efficiency and eco-friendliness. Traditional processes often produce significant waste. Embracing new technologies can help reduce this.

Tips: Start by assessing your current processes. Identify waste streams and explore ways to reuse or recycle them. This can lead to innovative solutions.

Sustainable practices also include energy efficiency. Energy-intensive processes often lead to higher emissions. Modifying reactions to occur at lower temperatures can save energy. Exploring renewable energy sources is another avenue.

Tips: Regularly review energy consumption. Implement monitoring systems to track usage. Small adjustments can lead to big savings over time.

Incorporating sustainability into chemical processes is not easy. It requires a shift in mindset. Engineers must be open to experimentation and fail-safe designs. These changes can lead to not just compliance, but also a more responsible industry. Developing sustainable chemical processes is a continuous journey, not a destination.

2026 Best Strategies for Chemical Process Development Techniques - Sustainability Considerations in Chemical Process Engineering

| Strategy | Description | Sustainability Impact | Example Techniques |

|---|---|---|---|

| Green Chemistry Principles | Utilizing chemical processes that reduce or eliminate hazardous substances. | High | Atom Economy, Benign Solvents |

| Process Intensification | Improving efficiency and reducing resource consumption in chemical processes. | Medium | Microwave-assisted synthesis, Membrane reactors |

| Life Cycle Assessment (LCA) | Evaluating environmental impacts throughout the lifecycle of a product. | High | Cradle-to-Grave analysis |

| Biotechnology Integration | Using biological systems and organisms for chemical production. | High | Enzyme catalysis, Fermentation processes |

| Waste Minimization Techniques | Strategies to reduce waste generation in chemical processes. | Medium | Recycle and Reuse, Lean Manufacturing |

Related Posts

-

How to Succeed in the Fine Chemical Industry and Boost Your Business Growth

-

Top 10 Trends Transforming the Fine Chemical Industry in 2024: Insights and Data

-

Top 10 Catalytic Reactions You Should Know For Chemistry Success

-

What is the Role of Catalysts and Technologies in Advancing Green Energy Solutions?

-

How to Accelerate Your Catalysis Research for Breakthrough Discoveries

-

How to Improve Efficiency in Chemical Manufacturing Processes